Research: multi-perforated plates

My main research activities at CERFACS were related to the near-wall flow inside

aeronautical combustion chambers. My Ph.D. was funded through the

European Project INTELLECT-D.M. and was a collaboration with Turbomeca.

In the context of flow through a perforated plate, I have been a reviewer for International Journal of Numerical Methods in Fluids.

Indeed, for cooling purposes, combustion chamber walls are perforated. Through these perforations, the air flowing outside the combustion

chamber is injected. On the combustion chamber side, these injections

form a cooling film that isolates the wall from the hot burnt gases.

This cooling system is often called effusion cooling or

full-coverage film cooling.

Flow Dynamics around multi-perforated plates

-

Large-Eddy Simulations of the flow a perforated plate

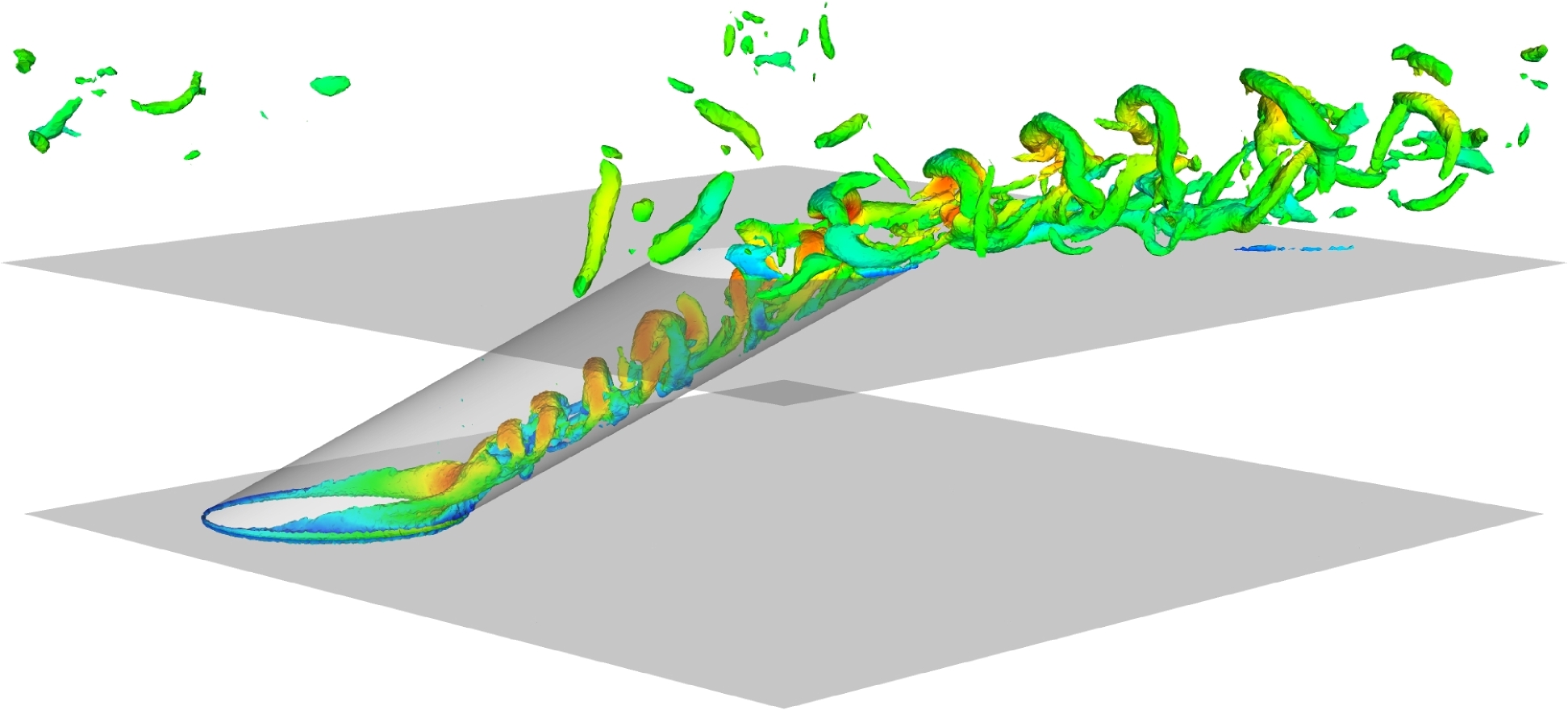

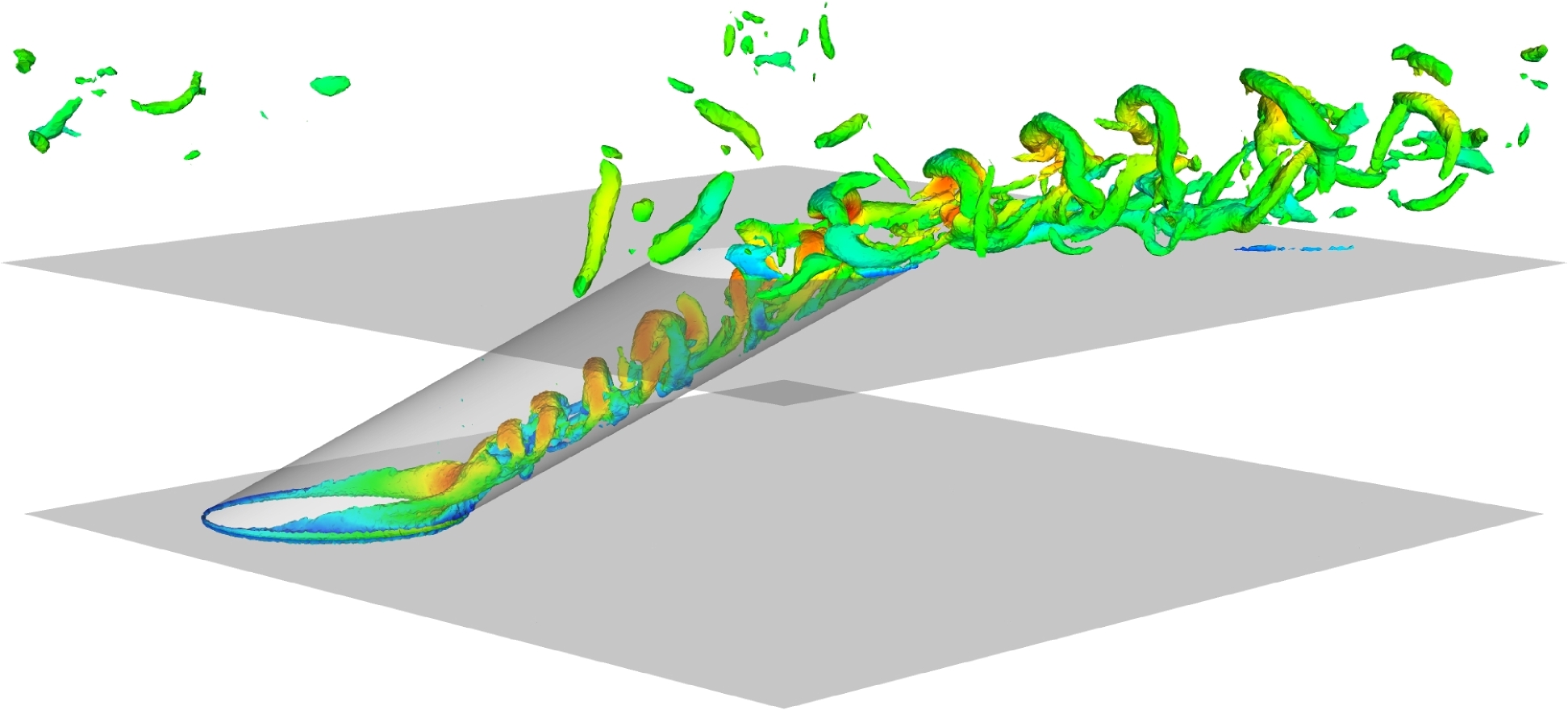

The flow around a perforated plate is not known very well. In order to be able to build a model of effusion cooling for combustion chamber computations, we needed to generate relevant data. This has been done thanks to wall-reslved Large-Eddy Simulations. In my Ph.D. we have chosen to design an academic configuration of effusion by computing the flow around an infinite perforated plate in a bi-periodic computational domain.

Instantaneous solution: iso-surface of the Q-criterion colored by velocity magnitude.

In the context of flow through a perforated plate, I have been a reviewer for International Journal of Numerical Methods in Fluids.

-

Near-wall modeling

From the numerical data coming from this wall-resolved LES, we have been able to build a homogeneous model that reproduces the average effect of effusion on both sides of the plate. One important result is that in a first approximation, the wall friction can be neglected compared to the inviscid fluxes induced by suction/injection of fluid through the plate. The model we have built comes from isothermal computations and does not assess the influence of temperature exchanges between the fluid and the plate. This work is currently addressed by Florent Duchaine at CERFACS.

Acoustics damping in perforated plates

Perforated liners are known to have a

potential effect on acoustics. They are for example specifically used

in post-combustion chambers to damp the acoustic waves generated by

post-combustion. The perforated liners in the combustion chamber may

also have a strong influence on the acoustics of the chamber. Notably

they may modify the acoustic modes of the chamber, and so have an

influence on combustion instabilities. I have worked on this topic with

Jean Dassé during his Master internship at CERFACS. We have

performed LES of the flow in a perforated plate with normal

perforations. We used the same strategy previously described, using

periodic conditions in the directions tangential to the plate to

reproduce an infinite perforated plate geometry. The outlet pressure

condition at the outlet of the domain is then pulsed to introduce an

acoustic wave. The reflection coefficient pf the plate is then

measured, with good agreement with existing experimental and

theoretical data.